Pad Printing for Injection Molding Manufacturers

Minneapolis Printing Services For Injection Molding Manufacturers

Pushing Your Product To Success With Collaborative Printing Services

Injection molding manufacturers come to us in the middle of their production process, often with significant initial costs and operations already invested in their products. From bottle caps to medical devices, UniversalPromo is proud to play a part in the process that makes your product successful! From the moment our work together begins, we keep you as the center of our focus, and measure success according to your standards.

We are a team of collaborative experts. Our graphic designers, engineers, print operators, and customer service representatives work together in-house to support every aspect of your project. From printing to assembly to packaging, we complete customized services using state-of-the-art equipment, supplies and programs. We adapt our time-refined methods to get the job done efficiently and accurately for your particular project, every time.

GRAPHIC DESIGN TURNS YOUR GOOD CONCEPTS INTO GREAT DESIGNS

UniversalPromo’s graphic designers specialize in the development and adaptation of graphics for print transfer. We use the latest design programs including the full Adobe Suite and Corel Draw to develop artwork that fulfills your objectives in terms of both function and design. Early in the project timeline we work with injection molding manufacturers to identify the shape and substrate of your product. Knowing the specifications of your product helps us best prepare graphics that will look great once printed on your product. Since many of our customers have a variety of products, our graphic design team will make sure your design can transfer to a variety of shapes and sizes for future orders!

For customers seeking support in original designs, UniversalPromo is here to help! We offer corporate identity kits that include original logos, letterhead, instruction manuals, posters, banners and more.

VERSATILE EQUIPMENT AND SUPPLIES FOR CUSTOM PROJECTS

Since injection molding manufacturers produce a diverse array of products, UnviersalPromo offers equally diverse capabilities! We serve injection molding manufacturers in variety of industries including medical, industrial, food, retail and more. We have capabilities for custom, semi-automated printing services on various substrates that include the following:

- Polyurethane

- Polypropylene

- Polyethylene

- Metal

- Glass

- PVC

- Pebax®

Once your product’s graphics are prepared for transfer, our engineering team continues preparing images and equipment for printing. We make custom nesting fixtures and select the proper dies or pads to ensure your images transfer crisp and clear onto every contour and curve.

THERE ARE TWO PRINTING METHODS IN WHICH UNIVERSALPROMO SPECIALIZES: HOT STAMPING AND PAD PRINTING.

Hot stamping imprints your design on rubber or metal dies using a foil of ribbon through a heat transfer process. The hot stamping printing heated the die with your design and presses a ribbon of foil against the substrate of your product. What results is a clear, enduring impression. UniversalPromo is proud to be a top distributor of high-quality foil and dies in the Midwest. Our customers can choose from foils in a broad range of colors and finishes to fit their specifications.

Pad printing transfers ink from a silicone pad to the substrate of your product through an indirect offset printing process. Pad printing is the best method for imprinting two-dimensional images onto three-dimensional surfaces.

WE COMPLETE PRINTING SERVICES ON A VARIETY OF PRODUCTS, INCLUDING BUT NOT LIMITED TO THE FOLLOWING:

Medical

- Syringes

- Implants

- Stents

- Monitors

- Pumps

- EKG machines

- Braces

- Catheters

- Pill cases

Food

- Food and beverage containers

- Plastic dishes and silverware

- Silicon bakeware and utensils

- Bottles and bottle caps

- Cutting boards

Retail

- Display cases

- Store fixtures

- Plastic toys

- Sporting goods

- Furniture

- Electronics

- Retail packaging

- Cartridges

Industrial

- Agricultural products

- Shipping containers

- Building and construction

- PVC pipes and fittings

- Fasteners, screws, nuts, clips, dowels, washers and spacers

For every pad printing project, UniversalPromo uses Class VI Medical Grade Inks that dry fast and endure sterilization methods such as water and chemicals. Class VI Medical Grade inks meet USP standards safety, making them safe for several applications that include medical implant devices.

OFFERING FDA COMPLIANT PRINTING SERVICES FOR VARIOUS INDUSTRIES

Many of our customers’ end users depend on their products for sensitive applications, such as medical implants and supplies. Your customers’ safety matters to us! Injection molding manufacturers can trust our 40 years’ of industry experience with printing and medical devices. UniversalPromo helps you meet rigorous FDA compliance standards through carefully regulated printing environments, comprehensive documentation of processes and supplies. We are familiar with standards for FDA approval processes, and will help ensure your product is printed, assembled and packaged safely and compliantly.

Our values of “fidelity” and “compliance” made UniversalPromo a leader in the medical device printing industry. No matter the application of your product, UniversalPromo will complete your project in a clean room environment. We maintain our clean room through careful regulation of personnel, equipment, and environmental factors such as airflow. Our clean room also undergoes regular and thorough cleaning. Such measures eliminate the risk of contamination.

We document every project for a few reasons. First, we want to ensure replicable results for future orders! If you wish to make adjustments in the future, documentation helps speed up modifications and ensures you get the results you want. Customers can request additional documentation for us, including material safety data sheets and ink compliance certificates.

OFFERING DIVERSE SERVICES UNDER ONE ROOF

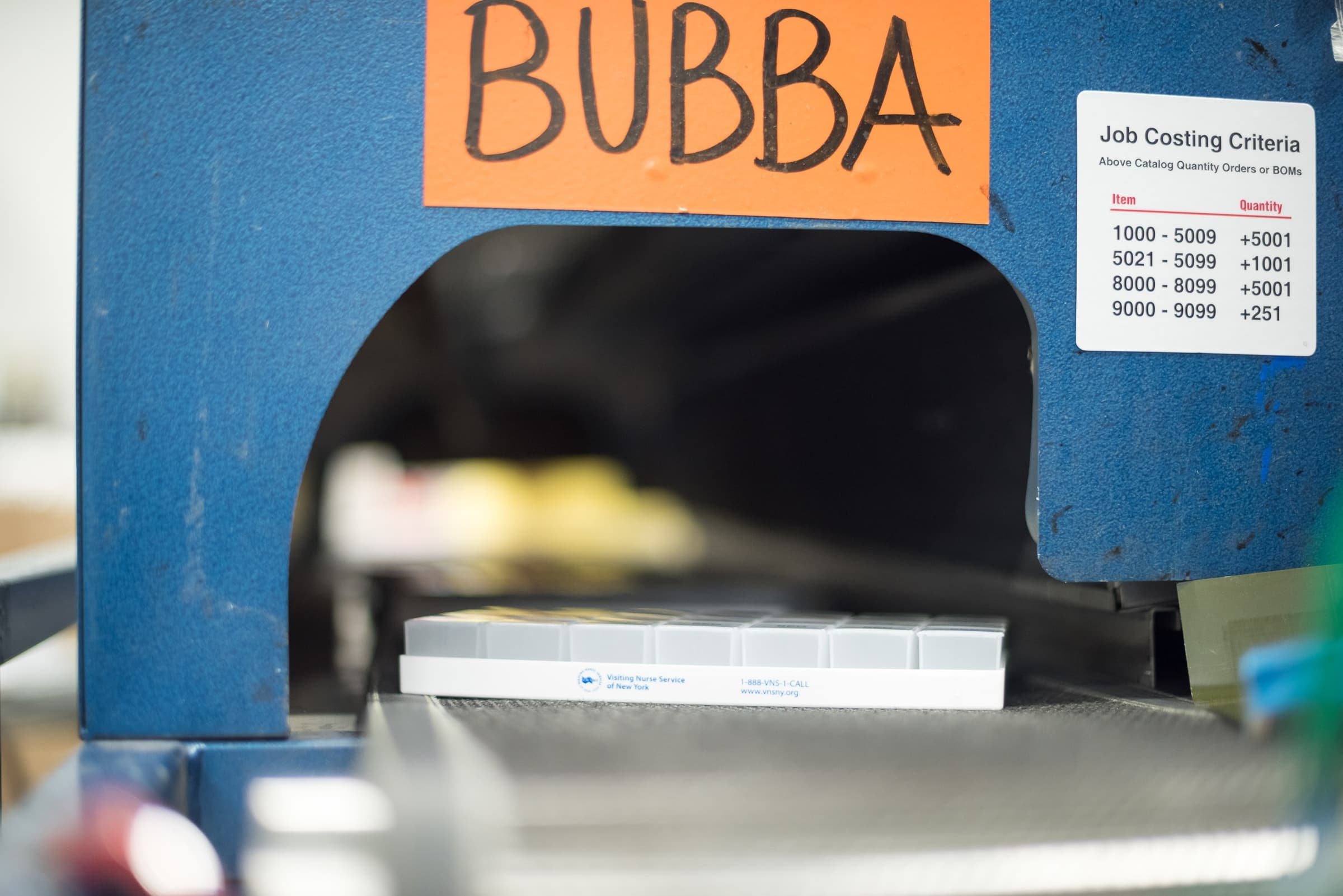

Keep your timeline shorter and your costs lower by letting UniversalPromo prepare your product for distribution. In addition to design and printing services, we offer assembly, kitting and packaging services from our production facility in Maple Grove, MN. Our production space allows us to ensure quick, high-quality project fulfillment.

- Product assembly: UniversalPromo offers assembly services of components or mechanisms in dedicated work cells, providing customers with documentation for compliance purposes as well as repeatability on future orders.

- Packaging: We offer diverse packaging supplies that include drop sealing, cello wrapping, blister packaging and shrink wrapping.

- Shipping: Once your product is assembled and packaged, UniversalPromo will arrange for your products to be shipped to their destinations!

We look forward to working with you soon! For any questions related to our design, printing, assembly or packaging services, feel free to contact us! We are happy to help.